Understanding Copper Pipe Sizes for Residential Water Lines

Did you know that nearly 30% of home plumbing issues stem from incorrectly sized piping? Using the proper dimensions helps maintain ideal water pressure and system efficiency. Here’s a homeowner’s primer on the sizing essentials for residential water projects.

Proper sizing depends on factors like flow requirements and wall thickness. Industry-standard 3/8″ copper tubing spans diameters from 1/4″ up to 8″, indicated by NPS (Nominal Pipe Size) versus true OD. Turn to Installation Parts Supply for specialist support to pair your home’s needs with regulation-approved products.

Copper remains a top choice due to its durability and corrosion resistance. From system upgrades to fresh installations, grasping these basics conserves time and wards off expensive errors.

Key Takeways

- Accurate sizing stops 30% of usual plumbing issues

- Standard diameters range from 1/4″ to 8″

- NPS labels don’t match real outer diameters

- Proper sizing maintains water pressure and efficiency

- Copper offers durability and corrosion resistance

- Specialist support secures regulation adherence

Reasons to Select Copper for Your Plumbing

Long-lasting plumbing begins by choosing the proper material—copper excels for these reasons. Boasting a half-century lifespan and NSF potable-water approval, it’s a go-to for residences. It uniquely blends durability with environmental responsibility.

Durability and Corrosion Resistance

Resisting rust and chemicals by nature, copper outlasts PVC and PEX. Smooth bore reduces friction, keeping water pressure steady. Practical tests confirm decades of leakless performance.

Installation Parts Supply carries certified quality products suited to your project. Although upfront costs rise, less frequent repairs yield savings over time.

Adaptability and Frost Defense

In frost-prone areas, its minor freeze expansion helps avert pipe bursts. This flexibility reduces the risk of costly winter damage. Combine with adequate insulation to optimize freeze defense.

Green and Antibacterial Advantages

Being wholly recyclable, it cuts environmental burden. Antimicrobial action curbs bacterial proliferation to boost water purity. Environmentally minded users find it superior to plastic substitutes.

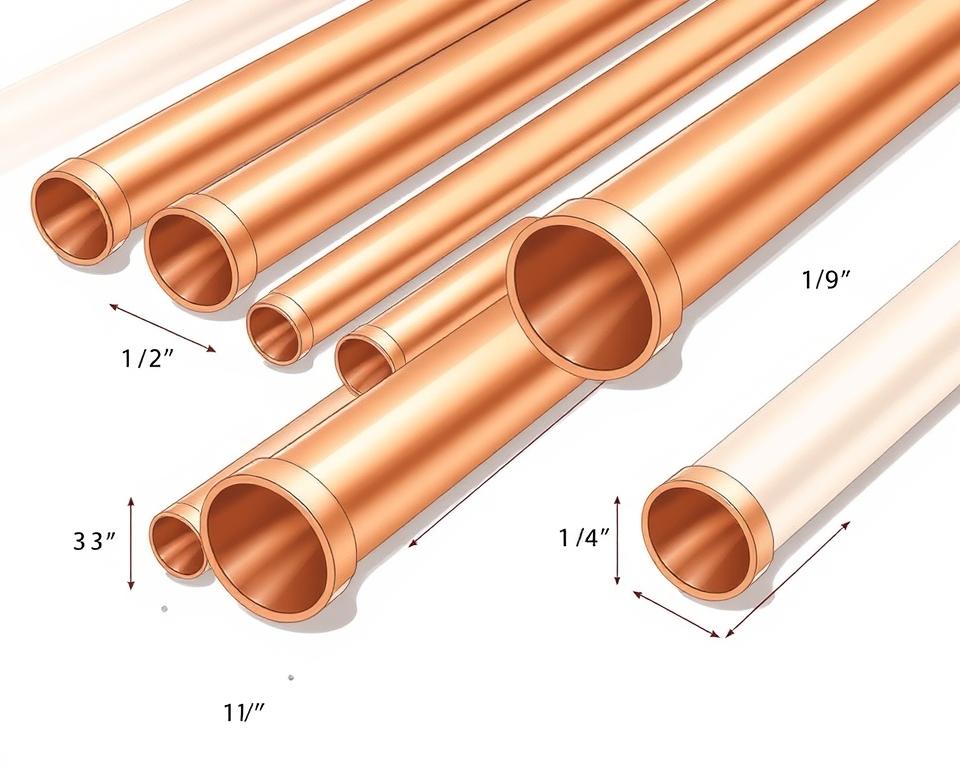

Understanding Copper Pipe Water Line Sizes and Types

Many homeowners struggle with pipe sizes—let’s break it down. Industry NPS labels don’t correspond to real outside measurements. As an instance, 1/2″ NPS measures 0.625″ across externally.

Nominal vs. Actual Pipe Dimensions

NPS numbers are labels, not exact measurements. Confirm true OD prior to purchase. A conversion chart helps:

- 1/4″ NPS corresponds to 0.375″ OD

- 1/2″ NPS = 0.625″ OD

- 3/4″ NPS corresponds to 0.875″ OD

Key Differences Between L, M, and K Types

Three copper variants lead in home plumbing. Wall gauge dictates where they’re best applied:

- Type L: Light-wall (0.040″ for 1/2″), ideal for most homes.

- Type M: Medium-wall (0.050″ for 1/2″), balances cost and durability.

- Type K: Thick-wall (0.060″ @ 1/2″), meant for high-pressure use.

Type M is suggested by Installation Parts Supply for broad residential use. Over 2″ spans usually need Type K for irrigation or business applications.

L-Type Copper Pipes: Slim and Adaptable

DIY enthusiasts benefit from L-type’s superior bendability. A slender wall cuts both heft and expense without sacrificing dependability. Available in rigid sticks or soft coils, it adapts to everything from HVAC lines to drain systems.

L-Type Uses and Constraints

L-type excels in low-pressure scenarios. With 0.040″ walls, it’s great for:

- HVAC refrigerant lines

- Drain-waste-vent (DWV) systems

- Residential water supply (below 80 PSI)

Not for high PSI—opt for Type K if stress exceeds limits. Coils (max 50ft) ease around corners but must be bent cautiously to avoid kinks.

L-Type Sizing and How to Install

Available in sizes 1/4″–8″, most often:

| Form | Max Length | Best For |

|---|---|---|

| Rigid | 20ft | Straight runs |

| Coiled | 50ft | Tight spaces |

Beginners will find rigid lengths, as recommended by Installation Parts Supply, the easiest to cut and solder. For large projects, coiled options reduce joint counts, saving time and potential leak points.

Type M Copper: Balanced Performance

With cost and strength balanced, M-type is ideal for today’s residences. A mid-thickness wall manages daily use without breaking the bank. Approved by NSF for water and gas, it works in kitchens, baths, and heating.

Where M-Type Shines

Great for both hot and cold feeds, it sustains consistent water pressure. Rigid 12ft lengths suit straight runs, while 100ft coils adapt to tight spaces. Typical uses cover:

- Drinking water distribution

- Medical gas lines (oxygen, nitrous oxide)

- HVAC refrigerant lines

M-Type Gauge & PSI Ratings

Sits midway between L and K in gauge and strength. With 0.050″ walls, it tolerates up to 150 PSI without failure. Compare key specs:

| Type | Wall Thickness (1/2″) | Max Pressure | Best For |

|---|---|---|---|

| L | 0.040″ | 80 PSI | Low-pressure DWV |

| M | 0.050″ | 150 PSI | Residential supply |

| K | 0.060″ | 200 PSI | Irrigation |

Installation Parts Supply stocks M-type in all standard sizes. Combine with proper flare connectors for gas lines to secure seals. Allow slight expansion gaps in hot water runs to accommodate thermal movement.

Type K Copper Pipes: Heavy-Duty Performance

For ultimate robustness, choose K-type in rigorous settings. Thick gauge and strong PSI rating enable industrial and subterranean applications. It outperforms slimmer options by standing up to crushing and corrosion.

Heavy-Duty Use Cases

K-type thrives in extreme conditions. With 0.060″ walls, it tolerates 200 PSI, suitable for:

- Underground irrigation systems

- Commercial HVAC refrigerant lines

- Fire sprinkler networks

For buried lines, Installation Parts Supply recommends 18″ minimum depth. Use compression connectors tightened to 25 ft·lb to seal joints.

Installation Tips for Rigid vs. Coiled Forms

Select between stick or coil based on needs. Rigid 12ft sticks suit straight runs, while 50ft coils navigate obstacles. Compare performance:

| Form | Best For | Limitations |

|---|---|---|

| Rigid | High-pressure mains | Requires more fittings |

| Coiled | Trenchless installations | Risk of kinks if bent sharply |

In irrigation layouts, allow 10% for thermal growth. Never bend rigid pipe by hand—use a bender or risk flow-reducing kinks.

Installing and Caring for Copper Pipes

Following best practices leads to long-lasting, leakless service. Whether you’re a DIY enthusiast or hiring a pro, understanding the basics saves time and avoids headaches. Use these approaches for solid, durable joints.

Permanent vs. Temporary Connection Methods

Select the joining style that fits your task. Heat or compression yield permanent bonds; non-permanent lets you tweak later. See which suits you best:

| Method | Pros | Cons | Best For |

|---|---|---|---|

| Soldering | Strong, permanent | Requires skill | Water supply lines |

| Compression | No heat needed | Bulky fittings | Tight spaces |

| Push-Fit | Quick installation | Higher cost | Emergency repairs |

Soldering Procedure

To solder properly, proceed as follows:

- Clean surfaces with emery cloth.

- Coat each piece evenly with flux.

- Heat evenly with a torch until the flux sizzles.

- Feed solder to the joint; capillary action pulls it through.

Use flameproof gloves and ensure proper ventilation. Find NSF-approved, lead-free solder at Installation Parts Supply for water systems.

Preventing Leaks and Freezing Damage

Use foam insulation on pipes in cold spots. Install insulating sleeves on wall-penetrating sections. To fix minor issues:

- Check joints annually for green corrosion (a sign of leaks).

- Hang horizontal pipes at 32 inches intervals to avoid sag.

- Install freeze-proof faucets in cold climates.

Annual inspections catch minor issues before they escalate. Keep a basic toolkit handy for quick fixes—adjustable wrenches, pipe cutters, and Teflon tape cover most scenarios.

Wrapping Up: Choosing Copper Pipes

With good planning, your plumbing will last—remember these highlights. Pick the correct gauge and diameter to maximize durability. Remember:

- Type M is best for homes; Type K for demanding uses

- Right sizing ensures steady pressure and leak prevention

- Freeze protection is critical in cold climates

Lean on Installation Parts Supply’s expertise to make selection easy. Certified solutions with quality warranties keep your plumbing systems running perfectly.

For support, grab our free guides or arrange a consultation right away. First-time buyers get exclusive discounts—start your project right!